Now that we have removed all the covers of the battery box, let’s have a look at the molten-salt (Ni-NaCl) battery that was used on this Renault Twingo. It is a pity really that I have to remove it: These batteries would be very environmental friendly, as the components of the battery are widely available without major impacts on the eco-system such as extensive mining etc.

If you want to read more about these batteries, check this Wikipedia article.

Here you can see the main battery with the HV and communication connections on the right side.

There were a few tests for the use of these batteries in the automotive industry. The first series of the Ford/Pivco Think were also powered by these batteries. In order to work, these batteries need to be kept at an operating temperatures of about 300 degrees Celsius / 570 degrees Fahrenheit, in order to keep the salt crystals in a liquid form. The heat is generated primarily by the chemical reaction within the battery while charging/discharging. If the battery is left idle, an external power source needs to be applied in order to keep the chemical reaction alive.

In a car, this means that the car must be plugged in when leaving it idle for more than 24 hours, otherwise the salt would crystallise and become solid, which would mean that the car needs to be heated up with an external power source for about 30 hours in order to liquidify the salt before the battery is ready to operate again, and the car wouldn’t be usable during that time.

Plugging in the car at home wouldn’t generally be a huge problem, as it can be plugged into a normal household socket and it draws only a very small amount of energy, just to keep the chemical reaction alive. But of course the handling is a bit less carefree than with a traditional car, so that’s maybe one reason why the Ni-NaCl battery never got a more widespread use in the automotive industry, which is a pity really. The second reason might have been that there are only two serious larger-scale manufacturers of these units globally, which resulted in a very limited support network for these batteries. Ask some early users of the Think vehicles for their experience, and they will all tell you the same: The battery was absolutely great as long as there were no problems. The smallest problem however more often than not meant the end of life of the battery (in the better case) or (in most cases) even the whole car, as nobody was able to actually diagnose or even fix these batteries. That’s probably also the reason why most of the Think vehicles were gone pretty quickly, even in Norway where they had quite some success in the very beginning. The ones still on the road underwent a similar surgery as I am planning on my Renault Twingo actually.

And here’s a better look at the connections:

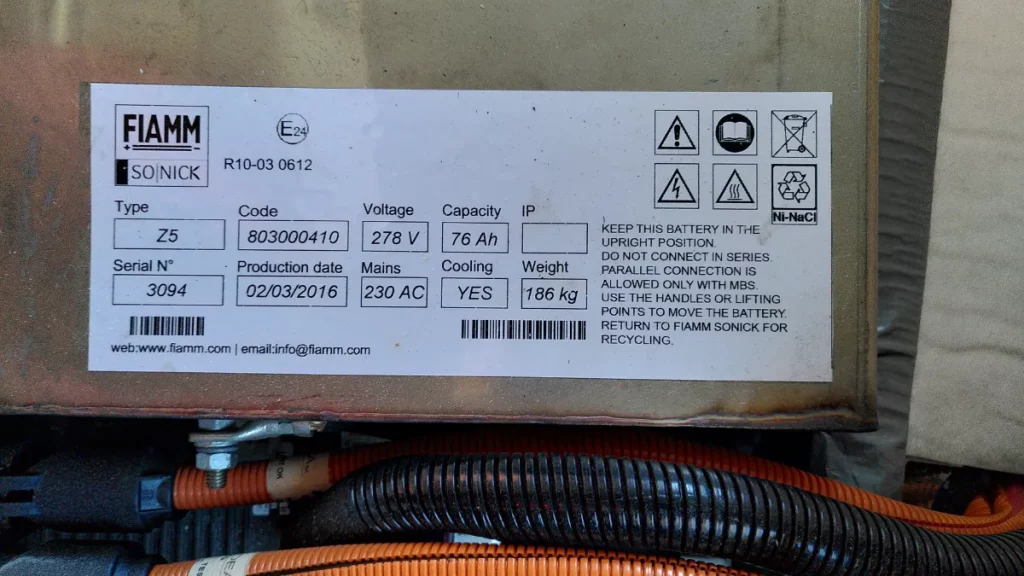

And this is very interesting now: The technical specs of this battery block. As you can see, the capacity is approx. 20 kWh, which considering the battery dimensions is a surprisingly good density. And another thing is quite surprising: This block has been built quite recently if you look at the sticker, the manufacture date reads March 2016!

The problem with the battery is that there are plenty of errors on the system, indicating either a isolation problem or indeed a faulty cell. It is quite hard to get these things diagnosed as there is little knowledge around on these special batteries.

The main use of this kind of batteries nowadays is grid storage, which makes a lot of sense especially also as a network buffer for renewables (e.g. solar), where you could collect and store energy from the sun during the day and then power your appliances at your house in the evening or at night.

The plan now is to see if Fiamm/Sonick are willing to diagnose the battery, and if there’s a chance to bring it back to life I might indeed be using it in a future solar application!