So after we discovered in the last post that the total Voltage of 6 Tesla modules would only be half of the required value for the Renault Twingo, let’s have a quick look at a different option just for the fun of it:

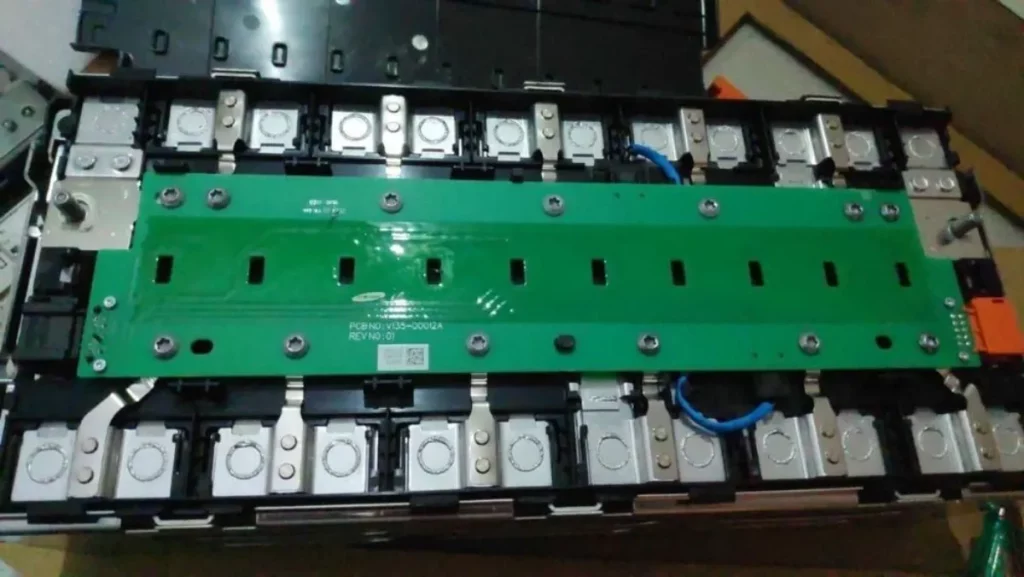

I have been offered a set of brand new Samsung SDI LX86 modules. These are Li-Ion modules configured in 12s1p with a nominal voltage of 43.2V (so double the value of the Tesla modules, as these here are in 12s whereas the Tesla modules are 6s). The Total capacity of a module is 2.07 kWh, 12 kg each. These modules are used in Ford hybrid vehicles (PHEV) such as the Ford Kuga PHEV.

The module measurements are 355 x 151 x 108 mm. So again if we have a quick look at the battery box measurements (800 x 520 x 280 mm) we can see that it would be possible to fit 12 modules into the box.

If we make the same calculation like for the Tesla modules, we would put 12 of these modules in series, which would result in 12 x 43.2V=518.4V. As you can easily see, this is much too high, as we were looking for about 270V. So if with the Tesla modules we were only half the value, here we have nearly double the value! So we will need to find something in between.

Let’s do a quick calculation on density and capacity: 12 x 2.07kWh=24.84 kWh total capacity, 24.84/116 Litres = 0.214 kWh/Litre of energy density in the battery box. The Tesla solution would have had a density of 0.274 kWh/Litre in this box, so these Samsung SDI modules are nearly 20% less dense than the Tesla modules in this configuration.

But of course our main problem is the voltage here. If it would be possible to create two strings of 6 modules (2p6s), we would be pretty perfect (6 x 43.2=259.2V). Unfortunately, splitting packs into parallel strings creates a whole lot of complexity on the BMS and safety side. So unfortunately I had to abandon this route, even though I would have got these modules at a very convenient price.

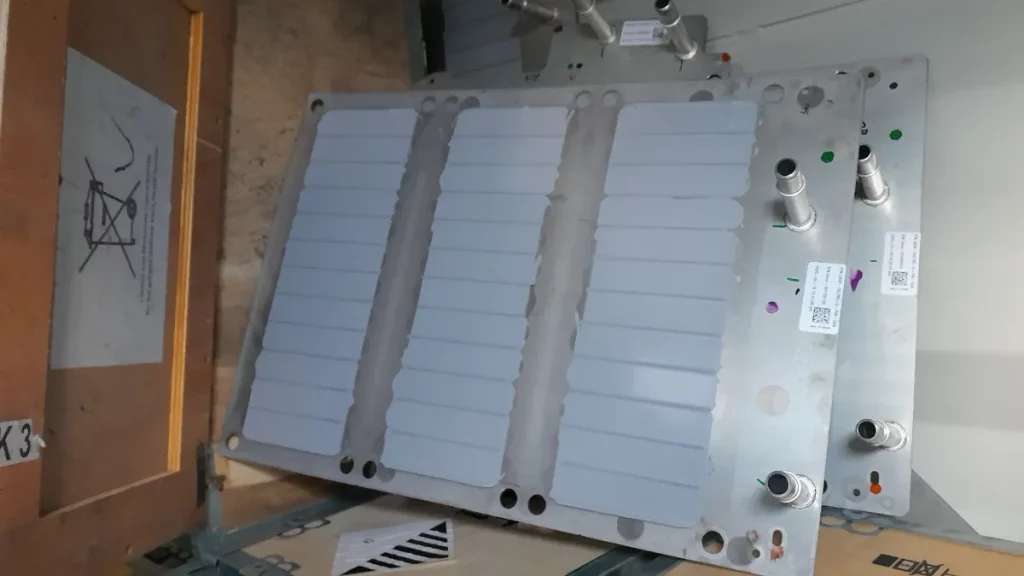

Maybe you are interested how cooling of these modules would work. As you might have learned on the previous post, the Tesla modules have an integrated cooling circuit. These modules here don’t have any plumbing for cooling included, so here we would work with cooling plates. The modules would be “glued” to the cooling plate with a heat transfer film. Other modules such as e.g. CALB-modules work in a very similar way.

So again, today we learned a lot about a specific battery technology, without finding a solution for our problem.