As the output shaft from the electric motor is considerably different than the crankshaft from a petrol engine, we need to fabricate a custom coupler to bolt the flywheel onto the electric motor in order to transfer the force/torque from the motor through the clutch and gearbox to the wheels.

The old coupler looked like this:

I drew up a new coupler for the motor in one of my first ever CAD drawings:

I sent the file to a machining shop near Milan to get it manufactured, together with its key to block it on the motor shaft. Here is the freshly machined part when I got it back from the shop by international courier (remember: This was spring 2020 so no international travel allowed!):

In order to fit it on the shaft I heated the coupler in our family oven (don’t ever tell my wife please):

As you can see, the coupler went on perfectly. The oven probably did the trick 🙂 !

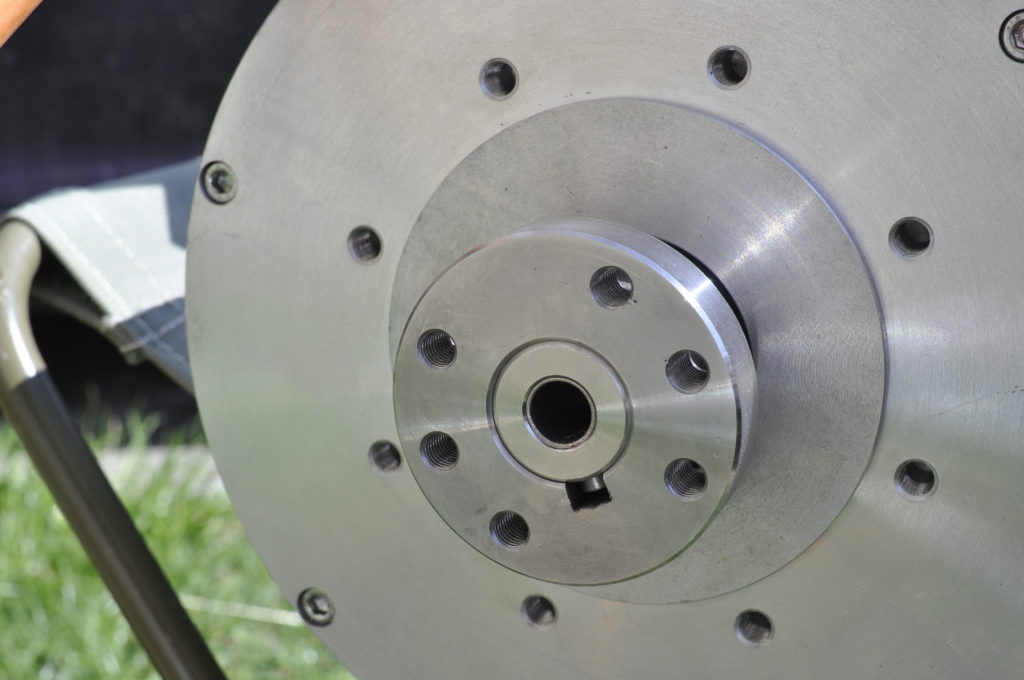

On this coupler, I then mounted the flywheel with its four secured bolts. This is basically what you can see in the next picture, and it means that we can get the power up to the flywheel by now, which corresponds to the old setup where the crankshaft of the engine would spin the flywheel.